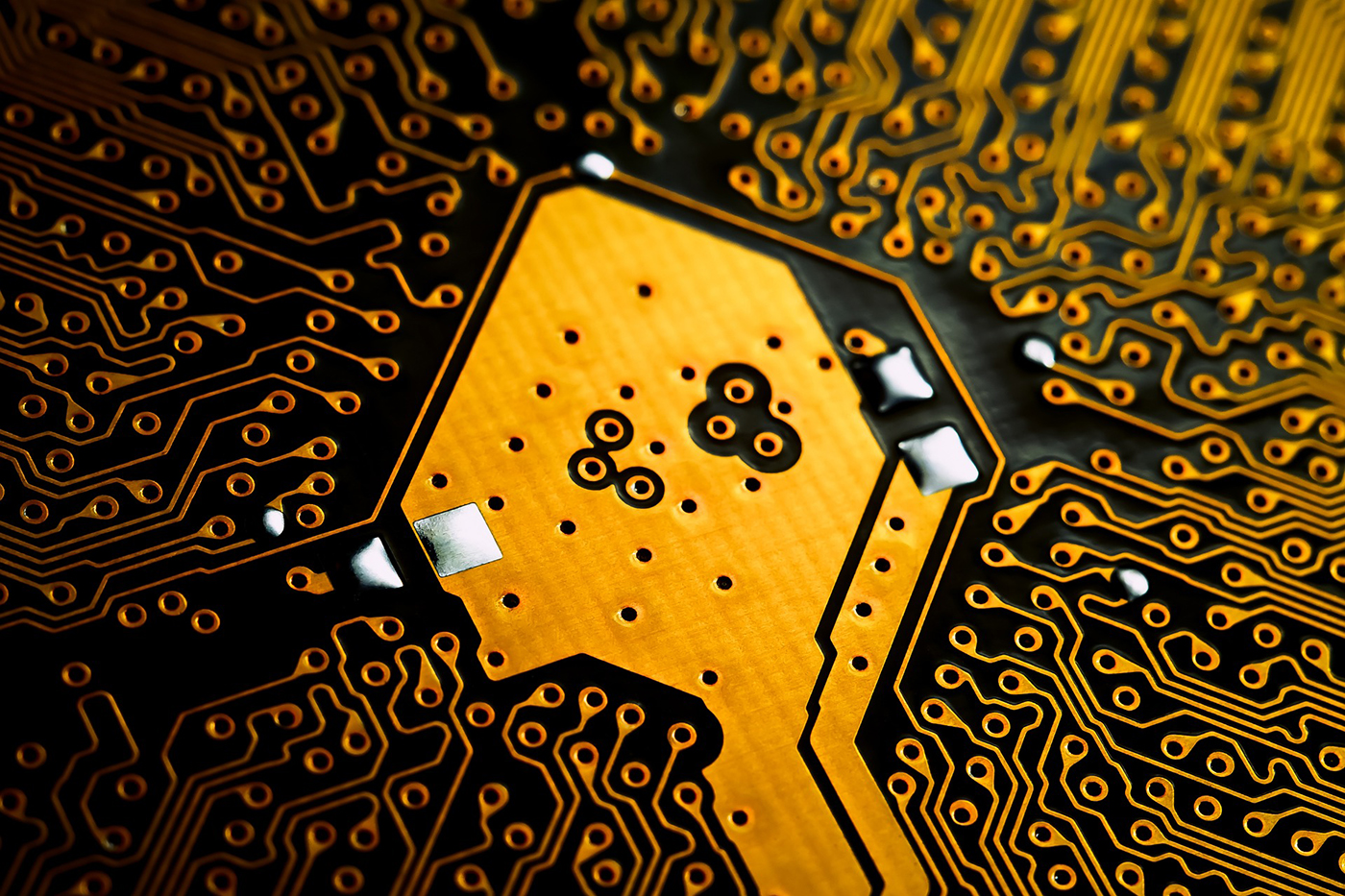

Electronic Component Shortage Model Mitigation Program

Increasingly long lead times for electronic components have been a problem for the electronics manufacturing community for months, if not years. The bad news: this trend is expected to continue for the foreseeable future. The good news: there are strategies that can strengthen your organization's supply position and mitigate shortages.

Uncertainty is a constant reality in today's manufacturing environment.COVID-19 will likely remain the primary reason for the electronics industry's purchasing slowdown. The new administration guiding U.S. policy has put tariffs and trade issues under the radar - and the U.S.-China trade war will continue, Dimensional Research writes in its Jabil-sponsored report "Supply Chain Resilience in a Post-Pandemic World."

Supply chain complexity has never been greater. Component shortages are causing strain and impacting end-of-life, meaning that a two-cent component can trigger a production line shutdown. Supply chain managers must deal with trade disputes, climate change, macroeconomic shifts and natural disasters. They often lack an early warning system before an efficient supply chain becomes ineffective.

Business leaders agree. "Business is stronger than expected and demand for many products has increased," said one electronics industry interviewee. "Volatility continues because of the very present epidemic and associated risks.

Electronics manufacturers need to work with their key supply partners to ensure that products with critical components are available in the next few months. Here are five areas where your channel partner can help you limit lead time variability.

1. Design for longer lead times for electronic components

Consider critical component availability and lead time risks early in the product design process. Delay the selection of interlocking components until later in the process. For example, create two PCB layouts early in the product planning process, then evaluate which one is better in terms of availability and price. Channel partners can help you identify components that may have limited delivery times, giving you the opportunity to find more readily available alternatives. With a broader supplier base and access to equivalent parts, you can eliminate potential pain points.

2. Leverage vendor managed inventory (VMI)

A strong distribution partner has the buying power and network connections to source the parts you need. By purchasing products in bulk and storing them in global warehouses, distributor partners can offer VMI programs to ensure that products are available when and where they are needed. These programs allow for automatic replenishment and avoid stock-outs.

3. Purchase components in advance

Once the bill of materials (BOM) or product prototype is complete, purchase all critical or potentially hard-to-get components. Focus on companies with the longest lead times for electronic components. Because this strategy can be risky due to changing markets and products, reserve it for critical projects.

4. Adopt transparent communication

Establish and maintain close contact with key channel partners. Share sales forecasts early and often so you can meet actual demand. Manufacturers can work with their manufacturing customers to develop regular, repeat purchasing programs to maintain a steady flow of parts through the plant.

5. Look for unnecessary latency

Every process can be improved. Distribution partners can help identify more localized sources or faster shipping methods to save time in acquiring components.