Superior obsolete material management solutions

Our robust quality processes are implemented in all of our global logistics centers. This enables us to source and deliver the highest quality obsolete components to our global customers on time, every time.

Component Lifecycle Management

You'll find preventive maintenance and decision support services in our Life Cycle Assessment (LCA) solution.

Inventory management, especially wound closure, can be challenging, time-consuming and highly variable, leading to wasteful inventory and high costs. We help customers control purchasing and eliminate excess wound closure inventory while maintaining supply levels, in-depth reporting and integration with materials management, operational reviews, and the ability to extend management to other product categories.

Are you looking to sell surplus inventory that cannot be returned to the original supplier? We have helped many of our partners sell their backlog of electronic components quickly and efficiently.

If you are an OEM or EMS, we can show your excess inventory to customers worldwide and help you sell it easily. No matter where you are, we will provide you with an efficient channel to sell your surplus components.

This not only prevents usable equipment from prematurely going into landfills, but also bypasses the resource taxation process by first recycling only a portion of the equipment and then using the energy to repurpose the material for other uses.

Data erasure, especially automated data erasure, simplifies the process of preparing devices for the circular economy without fear of sensitive data being extracted. This also provides affordable technology for homes, businesses, schools and global communities - all without relying on the creation of new devices.

Because electronics are produced and recycled globally; because they contain toxic and environmentally harmful substances and are highly resource-intensive; reducing impacts through better product selection and management can have a positive impact on human health and the environment around the world.

The UNU StEP initiative estimates that the global volume of e-waste could increase by 33% between 2013 and 2017.

The United States generates more e-waste each year (9.4 million tons) than any other country. (UNU tackles e-waste)

The EPA estimates that the U.S. consumer electronics recycling rate rose to 40 percent in 2013, up from 30 percent in 2012.

Discarded electronics create waste and liability issues. Proper disposal is a regulatory issue mandated by U.S. state and federal environmental protection agencies. Many large organizations continue to fail to comply with regulations designed to protect the environment and human health from e-waste.

Despite landfill bans and e-waste collection programs across the country, it is estimated that about 40 percent of the heavy metals in U.S. landfills come from discarded electronics.

The U.S. Environmental Protection Agency's Energy Star estimates that if all computers sold in the U.S. were Energy Star compliant, end users could save more than $1 billion in annual energy costs.

The mining and manufacturing of more than 40 elements used in the production of electronic devices consumes large amounts of energy and water and produces toxic byproducts and emissions.

Even in the most technologically advanced electronics recycling systems, most of the resources extracted and processed are simply lost.

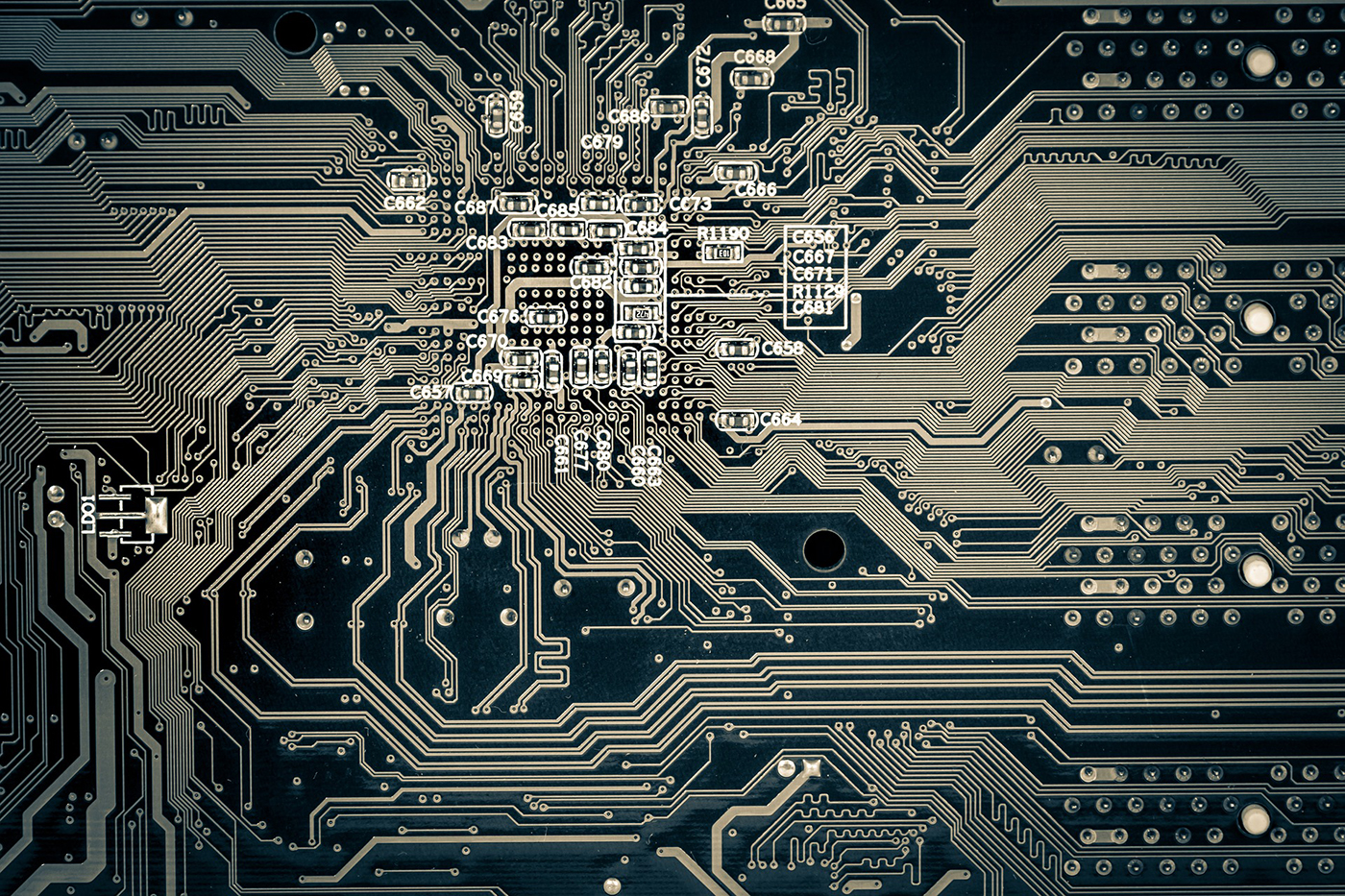

Creating an integrated circuit on a 30-cm wafer requires about 2,200 gallons of water, including 1,500 gallons of ultrapure water - and a computer can contain a large number of these small wafers or chips.

Electronic components are sourced from minerals and materials around the globe. Global Reporting Initiative (GRI) standards include identifying hot spots so that they can be avoided whenever possible. For example, in areas of the world where lawlessness and potential human rights violations are prevalent, one might consider sourcing from other parts of the world. This is the benefit of supporting the purchasing power of economies and practices that are good for human health and the environment.

Global e-waste recycling practices are well documented. It is estimated that only 29% of e-waste globally utilizes formal (i.e., accepted best practice) recycling channels. The other 71 percent flows into unregulated, uncontrolled practices in which nearly all product components and materials are discarded and, in addition, workers who handle these materials are exposed to toxic and potentially harmful substances such as mercury, dioxins and heavy metals. These components are then typically released into the environment, causing local and global hazards.